Technical Readiness Level Chart Dod – By clicking Continue Join or Sign In, you agree to the User Agreement, Privacy Policy and Cookies Policy.

Grant managers and investors want to understand how “ready” your technology is the main time. The scales used are by no means accurate. They also depend on the integrity of the inventor to be fair to readiness. However, the scales used are almost general matched. So it’s worth knowing about them.

Technical Readiness Level Chart Dod

MRL is usually a ranking level in production, although it can also mean market readiness. These two are not unrelated.

Dod Manufacturing Readiness Level Definitions

Technology Readiness Levels (TRL) are a method for evaluating the maturity of technology at the program. The scale was developed in the 70s of NASA. The US Department of Defense has used procurement and awards since the early 2000s.

The NASA TRL list is not legible here, but at the end of the article all the level definitions will be written.

The TRL level image as such is not readable, but the general version of the levels is given as an attachment.

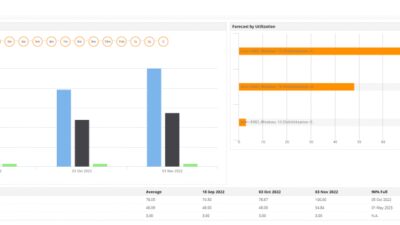

After the diagram description is reached, the number of TRL is obtained. For example, successful achievement in the TRL 4 (laboratory environment) does not move the technology to the TRL 5. TRL 5 is achieved when there is a component level validation in the relevant environment. The technology remains in the TRL 4 until the relevant environmental validation is complete.

What Are Technology Readiness Levels (trl)?

Energy Department in the technical market process: Technique readiness is usually measured on a nine -point scale, called the Technology Readiness Level (TRL). Market Readiness (MRL) refers to market readiness to adopt and adopt new technology.

This TRL list comes from NASA using NextFlex.us. The MRL list comes from the Defense Department using NextFlex.us.

TRL 1 observed and reported basic principles: transition from scientific research to applied research. Essential features and behavior of systems and architectures. Descriptive tools are mathematical formulations or algorithms.

TRL 2 Technology Concept and/or Application Formulated: Applied Studies. Theory and scientific principles are aimed at a specific scope to define the concept. The application characteristics are described. Analytical tools are designed for application simulation or analysis.

Us Dod Ecosystem Map Overview

Analytical and experimental critical function and/or characteristic concept evidence: Proof of conception validation. Active research and development (R&D) is started with analytical and laboratory studies. Demonstration of technical capabilities using a bread board or brass board, which is used with representative data.

Validation of the TRL 4 components/subsystem in the laboratory environment: Implementation and examination of prototyping. Integration of technology elements. Experiments with full -scale problems or data sets.

TRL 5 System/subsystem/Validation of components in the relevant environment: Careful prototyping test in a representative environment. Basic technology elements integrated with reasonably realistic supporting elements. The introduction of prototyping corresponds to the target environment and interfaces.

TRL 6 system/subsystem model or prototyping demonstration in the relevant environment (land or space): Implementation of prototyping for full -scale realistic problems. Partially integrated with existing systems. Restricted documentation available. The likelihood of engineering, fully shown in the actual system application.

Section 809 Panel

Demonstration of prototyping the TRL 7 system in the operational environment (land or space): System prototyping demonstration in the operating environment. The system is located in the operational system or on the scale, and most of the features are available for demonstration and testing. Well integrated with collateral and assistant systems. Restricted documentation available.

TRL 8 actual system completed and “mission qualified” using test and demonstration in the operational environment (land or space): the end of the system development. Fully integrated with operating hardware and software systems. Most users’ documentation, training documentation and maintenance documentation are completed. All functionality tested in modeled and operational scenarios. Testing and validation (V&V) is complete.

TRL 9 Actual Mission Proren using successful mission operations: fully integrated with operative hardware/software systems. The actual system has been carefully proven and tested in its operating environment. All documentation is complete. Successful experience. Keeping engineering support at the site.

There are ten MRLs (numbered from 1 to 10), which is associated with nine used trls. The final level (MRL 10) measures aspects of lean practice and continuous improvements in production systems.

Dod Digital Modernization Strategy

Although MRL is numbered, the numbers themselves are not important; Using digits is simply a convenient naming convention. The numbers denote a non -linear scale that identifies what maturity should be as a function of the program in the life cycle.

MRL 1: Impact of basic production identified. This is the lowest level of production. The focus is on the lack of production and the opportunities needed to achieve the objectives of the programs. Basic studies (i.e. funded with budget activity) begin in the form of research.

MRL 2: Production concepts identified. This level describes the application of new production concepts. Applied studies (i.e. funded by budget 6.2), which converts basic investigations to widely defined military needs. Usually this level of readiness in the S&T environment includes identification of materials and processes, paper research and analysis. There is an understanding of the possibility and risk of production.

MRL 3: Developed proof of concept production. This level begins validation of production concepts using analytical or laboratory experiments. This level of readiness is typical of technology in S&T funding categories in applied research and advanced development categories (i.e., funding with budget activities 6.3). Materials and/or processes are characterized by production and availability, but further evaluation and demonstration are required. Experimental hardware models are designed in a laboratory environment that may have limited functionality.

Biomedical Dod Technology Readiness Levels (trls): Medical Devices

MRL 4: Ability to produce technology in a laboratory environment. This level of readiness is characteristic of S&T programs in budget activity 6.2. And 6.3. Categories and acts as a output criterion for the analysis (MSA) phase of material solutions (MSA) approaching the point of turn. Technologies must be mature until at least 4. At this point, the necessary investments, such as the development of production technology, have been identified. Processes to ensure production, production and quality are introduced and enough to produce technology demonstrators.

Production risks for prototypes of buildings have been identified and reduction plans have been introduced. The target costs are set and the production costs have been identified. Design concept production assessments have been completed. The main design performance parameters, as well as all necessary special tools, capabilities, materials processing and skills have been identified.

MRL 5: Ability to produce prototype components in production in a given environment. This maturity level is characteristic of the midpoint during the development of technology development or in the case of key technologies near the midpoint of the Progressive Technology Demonstration (ATD) project. The technology had to mature up to at least the TRL 5. The industrial base is assessed to identify possible production sources. The manufacturing strategy is improved and integrated with a risk management plan. Identification of enabled/critical technology and components has been completed. Material prototypes, tools and test equipment, as well as staff skills are proven in components related to the production environment, but many manufacturing processes and procedures are still developed. Production efforts have been initiated or continued. Production assessments of main technologies and components are underway. A cost model has been created to evaluate the expected production costs.

MRL 6: Ability to create a prototype system or subsystem in the relevant manufacturing environment. This MRL is related to the readiness of the BTA’s decision to launch a acquisition program, entering the acquisition in the engineering and production development (EMD) phase. Technology had to mature at least up to TRL 6. It is usually considered a level of production readiness, which denotes the development and acceptance of S&T in the original system design. An initial production approach has been developed. Most production processes are defined and characterized, but there are still significant changes in engineering and/or design. However, the original critical component design has been completed and the evaluation of the main technology is complete. Materials with prototypes, tools and test equipment, as well as personnel skills, are proven in systems and/or subsystems in a given environment. A cost analysis has been carried out to assess the projected production costs compared to the target costs, and the program has implemented adequate risk reduction in order to achieve cost requirements or to set a new base line. This analysis should include design transactions. Harvest considerations are system development plans. Industrial capacity assessment (ICA) B is completed. Prolonged and main supply chain elements have been identified.

Bridging The Gap: Linking Prototyping And Technology Readiness Levels For Integrative Product Development

MRL 7: Ability to produce systems, subsystems or components in a representative environment. This production level of production is characterized by the average point of engineering and production development (EMD), which leads to the CDR assessment. Technology must be the way to reach the TRL 7. System detailed design activity. The specifications of the materials are confirmed and the materials are available to match the planned trial line design schedule. Production processes and procedures have been proven in a representative environment. Detailed trade studies and risk assessment are carried out. The cost model is updated with detailed designs, implemented at system level and tracked against the awarded goals.