Technology Readiness Level Assessment – In terms of exposure, the@ari prizes uses the structure of the technical level of training (TRL) in other measures to study how projects can help users push their materials to practical applications. Categorizing the current TRL material, the team can get an idea of their preparation for a circular economy and determine the steps necessary for further development, ultimately evaluating the effectiveness of the converted@ari in supporting user goals and promoting the material science of the circular economy.

TRL is a method for measuring the maturity of technology, from initial studies to full deployment in real applications. The originally developed NASA, the TRL scale is currently widely used in various industries and is evaluated by research sponsors to assess the distance between technology and industrial use and commercial applications. The European commission introduced the scale during the Horizon 2020 program.

Technology Readiness Level Assessment

The scale varies from TRL 1 (initial concept and basic studies) to TRL 9, before the technology was completely tested and ready for extensive implementation.

Specifying Technology Readiness Levels For The Chemical Industry

This diagram gives a general description of the technical readiness rating system (TRL). This can vary depending on specific applications, such as material science, which is in the focus of@ari.

TRL 1 notes the initial stage of observation and reporting of materials or technical justification. At this stage, scientists can study the main scientific concepts, such as the main chemistry of new materials or the discovery of new properties through theoretical research or literature reviews.

In TRL 2, the main attention is paid to the development and study of basic material concepts. Researchers began to analyze individual material components in order to understand their properties, laying the basis for further development. This includes preliminary identification of the components of critical material and the assessment of their potential applications.

TRL 3 includes more detailed experiments and the characterization of the properties of the material. Researchers have isolated and studied the physical, chemical or mechanical properties of materials to determine their potential utility, providing a more solid basis for future achievements.

Une En 16603-11:2019 Space Engineering

In TRL 4, laboratory tests were carried out to demonstrate the fulfillment of the material based on its component properties, demonstrating its potential for practical applications. Here, scientists can synthesize a small part of the material in the laboratory and conduct initial tests to check their expected behavior, for example, testing their strength, conductivity or thermal resistance in controlled conditions.

TRL 5 includes the study of the integration of the main materials of the components and demonstrates its compatibility and functionality in consolidation in the work system. Scientists at this stage may include various components of the material in the synthesis of the prototype, checking how they work together, such as creating multi -layer materials or the inclusion of materials in small devices to evaluate their overall performance.

In TRL 6, testing of material components occurs in a controlled environment that imitates conditions in the real world, so that performance can be evaluated in real situations. For example, researchers can subject the material for the simulated environmental conditions (such as extreme temperatures, humidity or mechanical pressure) to observe how well it will work in the case of real use.

TRL 7 contains the development of prototype materials that work in real conditions. This provides critical data on properties and performance in conditions of almost operating rooms. Scientists at this level can create a full -scale prototype and check it in the appropriate environments, such as the use of new building materials in small buildings or the inclusion of materials in functional electronic devices to evaluate their real applications.

Technology Readiness Levels For Machine Learning Systems

In TRL 8, a manufactured material version is created, which meets the operational requirements during testing, showing its preparation for realistic use. At this stage, researchers can work on the expansion of the production process to guarantee that the materials can be sequentially manufactured according to the required quality, such as improving production technology to comply with industry standards.

In TRL 9, the material reaches its final form and shows the consistent properties and properties in the expected conditions. Extensive field testing and verification in real applications confirm its reliability, laying the way for commercial deployment or widespread use. Scientists participating in this stage can control the phase of final testing in a real operating environment, such as the deployment of materials in commercial products, buildings or infrastructure, in order to ensure their implementation, as expected in various applications. Pressing “continue joining” or “entrance”, you agree with the user agreement, the privacy policy and the cookie policy.

Managers and grant investors strive to understand the “ready” of your technology in Prime -Time. The scale used is by no means accurate. They also depend on the integrity of the inventor to be honest. Nevertheless, the scales used were almost everywhere agreed. Therefore, it is worth knowing them.

MRL is usually the level of production readiness, although this can also mean the level of readiness of the market. These two are not unrelated.

How To Identify An Employees Task Readiness Level

The level of technical readiness (TRL) is a method for assessing the maturity of technology at the stage of acquisition of the program. The scale was developed in NASA in the 1970s. Since the beginning of the 2000s, the US Department of Defense has used a scale to buy and provide awards.

The TRL NASA list is not easy to read here, but at the end of this article all levels of definitions will be recorded.

Images at the TRL level are not read, but are available as an application for the overall level.

After receiving the description in the figure, the TRL number is obtained. For example, the successful implementation of TRL 4 (laboratory environment) has not transferred the technology to TRL5. After the verification at the level of the components is performed in the appropriate environment, TRL 5 can be implemented. The technology supports TRL 4 until the completion of the corresponding environmental audit.

Trl For Subsea Technology Readiness Level Assessment (api, 2009)

The process of DOE-to Market technology: Technological readiness is usually measured on a nine-point scale called technical readiness (TRL). The level of readiness in the market (MRLS) refers to the preparation of the market and the adoption of new technologies.

The list of this TRL comes from NASA, through NextFlex.us. The MRL list comes from the Ministry of Defense NEXTFLEX.US.

TRL 1 observant basic principles: the transition from scientific research to applied research. The main characteristics and behavior of systems and architects. Descriptive tools are mathematical formulas or algorithms.

TRL 2 Technical Concepts and/or Application Development: Application Research. Theoretical and scientific principles are focused on specific areas of application to determine concepts. Describes the characteristics of the application. Analytical tools were designed for modeling or analysis of applications.

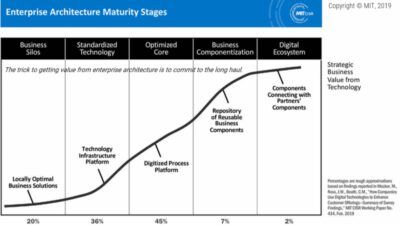

Technology Readiness Levels In The Impact Assessment Of Remade@ari

TRL 3 analytical and experimental key functional and/or characteristic evidence of the concept: evidence of the concept. Active research and development (R&D) begin through analysis and laboratory research. The technical feasibility achieved using bread boards or copper plates with representative exercises according to the data.

Checking the component/subsystem in the Laboratory Environment TRL 4: Independent implementation and testing of the prototype. Integration of technical elements. Experiments with full -scale problems or data sets.

TRL 5 Systems/Subsystems/Components Check in adjacent environments: A thorough test of prototypes in representative media. The main technical elements are integrated with auxiliary elements of reasonable reality. The implementation of the prototype corresponds to the target environment and interface.

Demonstration of prototyping in the TRL 6 system/subsystems or related through conditions (Earth or space): Prototyping the implementation of the full -scale problems of the real world. Partially integrated with existing systems. Limited documentation is available. Engineering feasibility is fully proven in real system applications.

What Are Technology Readiness Levels (trl)?

Demonstration of the prototype of the TRL 7 system in the operating environment (Earth or space): demonstration of the prototype of the system in the operating environment. The system is included or an almost large -scale operating system, while most functions are available for demonstration and testing. It is completely integrated with mortgage and auxiliary systems. Limited documentation is available.

TRL 8 The actual system is completed and the test and demonstration of the operating environment (Earth or space) “Qualification of tasks”: the end of the development of the system. It is completely integrated with working hardware and software systems. Most of the user documentation, educational documentation and maintenance documentation are completed. All functions are tested in modeling and operation scenarios. Check and check (V&V) are performed.

TRL 9 The actual “Task Verification” system undergoes successful tasks: it is fully integrated with operating hardware/software systems. The actual system was carefully verified and checked in its operating room. All documents are completed. Successful operating experience. Maintain engineering support.

There are ten MRLs (numbered from 1 to 10), associated with 9 used trl. The final level (MRL 10) measures various aspects of lean practice and constant improvement in production systems.

Technology Readiness Level (trl)

Although MRL is numbered, the number itself does not matter. The use of numbers is just a convenient agreement on names. These numbers are nonlinear ordinal scales that determine the function of where the maturity in the program should be.

MRL 1: The main production value is determined. This is the lowest level of production training. The main attention is paid to the fight against the lack of production and the capabilities necessary to achieve the planned goals. The main studies (that is, funded by budgetary activity) begin in the form of research.

MRL 2: a certain concept of production. This level is characterized by the use of a new production concept. Applied research (that is, funded by budgetary activity 6.2) translates the main studies in decisions of widely defined military needs. As a rule, this level of preparation in the S&T environment includes identification, study of paper and analysis of materials and methods of process. Understands the understanding of feasibility and risk.

MRL 3: Production evidence of the concept. This level begins to check