Technology Readiness Level Bc – The development of a successful strategy for mineral and treatment management is a critical aspect of each mining project. The plan must protect the environment, to meet the needs of the project and to pass the regulatory approvals. Since it can be difficult to understand the combination that technologies are currently accepted as best practices, they are often regulatory approvals, which are often the cause of confusion and disappointment. Despite the increasing arsenal of durable water treatment technologies, very few can obtain approval. Most mining judges use the best accessible technology processes, which are very useful to determine which technology can treat water. However, there is an aspect of feasibility that requires “the proof of the technology of the bat processing. The lack of a clear definition” proved was a debate problem to usually allow processes.

The new implementation of the levels of training of technology (TRL) for major mining projects in British Colombia brings clarity to the implementation of water treatment technologies and strategies to reduce resource control.

Technology Readiness Level Bc

In a regulatory context, the TLLs depend on the third stage of the BAT evaluations necessary for the common requirements of applications (Jair). There is a direct financial correlation between the water treatment costs during the mining operation, the cost of reproduction after the closure and technological selections of water treatment.

Alert Deluxe First Aid Kit

The TRL frame can be removed from it throughout my life. The use of the Guide to Evaluation of the Training of Technology (Tra) allows developers to better understand the specific conditions of the site and allow them to reduce the risk scenarios. By offering a common reference point, they help to accelerate the planning of communication and contact of the interested parties so that the project exceeds the confidence during the leave process and during the mine.

An inclusive challenge will be to determine whether the application of the Trar guide is consistent in any type of water treatment or if there should be different approaches to passive and active treatment.

Evaluation of technology preparation (TRA) is a tool used to evaluate the preparation of technology during research and development. The TRA guide certificate provides information on how Trar will be implemented. What is trl? And how are they determined?

The TRL scale, which was developed for the first time by NASA in the 1970s, is designed to measure and evaluate the level of maturity of any technology.

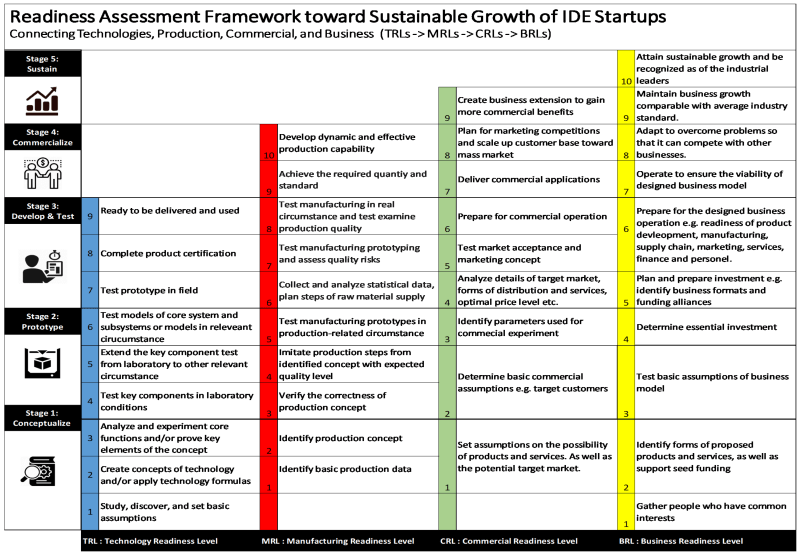

Product Innovation Management Model Based On Manufacturing Readiness Level (mrl), Design For Manufacturing And Assembly (dfma) And Technology Readiness Level (trl)

The process of progress through TRLS is widely called “maturation of technology, a typical example follows the following: basic research (level 1 and 2); research and development (level 3, 4 and 5); pilot and demonstration (6, 7 and 8 levels); and early adoption (level 9).

Innovation, Economic science and development (ISED) Canada offers wide guidance for the use of TLLs intended to apply to all types of technology. B.C. TRA orientation documents, most of the TLLs are open to the public from ISED and B.C. Regulatory processes for water treatment and welding control in large mines.

In the autumn of 2022, BC. Energy, mines and low carbon emissions (EMLI) and BC. The strategy of the Ministry of Environment and Climate Change (ENV) has issued two documents to guide the selection and progress of TRL in the mining sector. Levels for the preparation of temporary guide technology for the great Mines in British Colombia “(TRL guide; V02.00, 2022) and” Temporary technical guidance certificate for the evaluation of technology training “(Follow -up; V02.00, 2022) is unique.

B.C. TRL orientation documents offer clear TRL indicators for different levels of permissions. One of the principals of TRLS is the test environment of a technology. Essentially, a trl applies only to the specific operational environment in which it is tested. If an advanced technology should be distributed in a different operational environment, as tested, the technology decreases in TRL and should pass again without testing and maturation.

Cloud Readiness Assessment: A Complete Roadmap To Migration

This TRL guidance is an important step in integrating more modern water treatment technologies into the regulatory process for large minerals. It also offers clarity to turn new and developing technologies into full application.

In addition to determining the TRL of the technology, the orientation certificate describes as a “systematic, evidence -based process”, with primary objectives to determine the risks and gaps of knowledge in the progress of a technology (V02.00, 2022).

According to the TRA guidance certificate, any mining law (MA), the Law on environmental assessment (EMA) or the Law on environmental assessment (EA) is not a necessity of the regulatory processes. On the contrary, it is recommended to take place before these attempts. The document indicates:

“A trace is initiated and developed independently by the proposal. The parties, Howver 2022).

Technology Readiness Levels Are For Unicorns!

These documents clearly reveal that the company’s enterprise will be beneficial to accelerate the permit and review processes, avoiding the pursuit of potentially non -applied technologies. While a lower TRL technology can be monitored, it should be taken into account in the context of time (and uncertainties) programs associated with bringing technology to implementation. Based on this, a trace compatible with a bat evaluation can be suitable to ensure the efficiency of both processes.

He built wet tests in a mine in Ontario, which is performed by the mobile pilot -Maven Su and the environment. Credit: water and medium maven

TRLS Level 5 and over BC. All information should be allowed and all information should be collected under the specific conditions of the relevant site, but there is a difficulty, because it is not clear what will be considered relevant or specific to the site.

Active treatment systems usually obtain regulatory authorizations faster, because they change (controls) the conditions specific to the region. Can be controlled using dynamic variables specific to a number of regions. For example, the pH range can be modified before the basic stages of a water treatment station can be replaced or a temperature range can be fixed by heating. This eliminates a large amount of uncertainty associated with the variations specific to the field. In contrast, “passive” treatment systems should be changed to fulfill and approach the differences of the basic projections of the basic projects.

B.c. Bans Level 3 And Above Road Autonomy

This means that, even if a passive treatment technology has been previously applied on a full scale in other regions, it is necessary to apply it to a different place, because it should be modified for the specific conditions on the new site, it will be reduced from 8-9 to 5-7. Therefore, in order to implement these technologies, longer time programs must be taken into account. In addition, there is a risk that a technology will be developed for a particular site through several trl. This can be a major obstacle for the permission of water treatment technologies that emit more gas effect.

A potential solution to this difficulty is the active and semi -plated hybrid design of water treatment, which is sometimes called developed passive treatment (EPT). The emergence of EPT systems is conceived as a “happy environment” between asset and passive. Although an EPT system has higher capital expenditures than a passive system, daily operating expenses are significantly lower than an active system, and the application calendar is much faster and less risky than passive treatment.

An EPT system aims to work passively, but it is designed and built with the ability to open active properties. For example, changes in treatment needs (for example, flow or chemistry changes) or flow control or reactive additions can be applied in response to system disorders. This can help place the limits within the variable range needed to collect the information specific to the site.

Collecting data for the “specific field of field relevance” is one of the biggest challenges for all water treatment systems. Although tests are expected to be the most relevant, if a treatment system is designed for a different stage of mining life, it may not be possible to take the test early enough to improve the time test.

Blue Hydrogen Production And Markets 2023-2033: Technologies, Forecasts, Players: Idtechex

In these cases, the simulated environmental test is a useful tool. These are valid for TRL 3-6, but can also support higher levels of risk management plans that require additional development.

In simulated environments, the ability to control factors such as temperatures, lighting conditions, humidity levels, flows and chemical variables allows fast information to identify potential risks for greater optimization. This