Technology Readiness Level Offshore Wind – Beyond 2020 (IVT file and WDS) is completed. The data can now be used through the .stat data conductor, and the user can export the data to Excel and CSV data.

Successful mitigation strategies depend on the availability of technology and the development and expansion of technology at each stage of the process.

Technology Readiness Level Offshore Wind

Transmission and storage network. All stages of the value chain are technically prepared, and in the case of zoom, it must be developed as a tandem of the CCU.

Fixed Wind Foundations: An Independent Concept Screening Approach

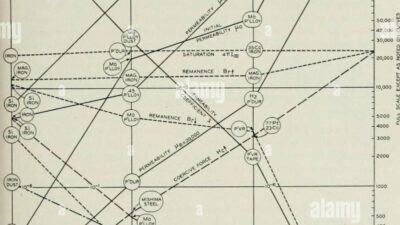

Capture, transportation, use and storage have already been placed on a large scale, but other technologies, including technologies that increase productivity and reduce costs per unit, require additional development. One way to evaluate where technology is from the laboratory to the market is to use the TRL scale. The TRL scale provides a general criterion that can be applied to all technologies to evaluate and compare technology in other sectors and in other sectors.

The TRL originally developed by the National Aeronautics and Space in the 1970s, the TRL, originally developed by the state administration (NASA), provides a mature time of this technology on a specific scale. It is widely used by research institutes and technologies around the world to set the current research priorities and design innovation support programs. 1 ~ 9 can be applied to all technologies. However, just arriving at a stage that can be considered commercially accessible (TRL 9) is not enough to achieve the energy policy goal, which is often important. For this reason, the TRL size used in this report includes two additional levels of preparation. One is a commercial and competitive place, but when there is development, it requires additional innovative efforts to integrate technology into energy systems and value circuits (Trl11), final and final and diversity. TRL is classified as four extensive preparation categories: prototype, demo, early acceptance and maturity. All CCUS technology and CCUS value chains, which are expected to play a role in sustainable development scenarios by 2070, are already in the prototype stage. See for more information. (2020a) and (2020b).

It is mature in the type of commercial technology that reaches a significant deployment and expects additional innovation. The technical type of this category includes all the design and the main components of TRL 11. Examples of hydroelectric and electric trains.

Although some structures are initial adoption of technology technology that requires policy support to reach the market and expand size, there is a competitive structure confirmed at the stage of demonstration and prototypes. The technical type of this category has the main design of TRL ≥ 9. Sea wind, electric batteries and heat pumps are examples.

Saipem And Cnr Join To Study Floating Wind Foundations

The demo of the technical type where the design is below the demonstration stage means that there is no main design in TRL ≥ 9, but at least TRL7 or 8 has no design. Cement furnace, electrolytic hydrogen ammonia and methanol and carbon capture of large batteries.

The prototype of technology technology in a specific scale prototype means that there is no basic design in TRL 7 or 8, but there is one or more design in TRL5. Examples of steel and dubif-production for electrolytic production is electrolyte production of steel in hydrogen steel.

TRLS and categories (prototypes, demos, early acceptance and maturity) used in this report are related to market entry as well as technology development phases. Today, most of the technologies in the early stages of adoption have already passed the entire cycle of technology development, but it is not displayed as “mature” because it has not been widely deployed because it is applied to most CCU applications. Therefore, a wide range of technologies are commercial and competitive, including many high -end CCU technologies, electric vehicles, sea winds and solar PV, but need further integration. Early adoption categories can increase the necessary political and legal frameworks, which can grow quickly as soon as possible.

Technology -large prototypes or more sophisticated stages. Each technology is at the highest level of preparation for the basic technology. At a small level of prototype, more details on the development of individual technologies for each of these technologies and structures, for example mineral CO2 storage.

Andrei Moscal, Author At Corewind

For ER. Many other applications have been proven in the last decades, but they are initially accepted, such as chemical absorption due to electricity production, hydrogen production of natural gas, and cavity compression.

In cement and iron and steel production, capture is still in the stage of demo or prototypes. Many COs in each of these potential new applications

In the policy scenario specified in the sustainable development scenario, almost two -seconds of the total emissions of the CCU by 2070 are derived from the current prototype or demonstration stage. Another third comes from mature or early adopted technologies, which can lead to improvement of additional technology and reducing costs and increasing quickly. From decades to 2030, these technologies in energy and fuel conversion, including hydrogen production, contribute to about half of the cumulative emissions in the scenario. Most of these applications are based on the absorption of chemicals.

The main improvement of extensive technology in the prototype or demonstration stage today. It is an important program that begins a key role for decades, but it still requires short -term stimuli of RD & D and includes electricity and cement and chemicals, BCC and common chemical absorption.

United 2nd Webinar

Capture for iron and steel production. Some applications have a lot of technologies because they represent several entrepreneurs with a variety of capture technologies (eg electrical production), other energy conversion processes, or other entrepreneurs with a common production process.

The deformation of a synthetic hydrocarbon fuel, which plays an important role in the late projection period, requires significant research and research to start developing in the 2030s. Initial DAC development efforts can provide important technologies in preparation for slower risks than innovation or commercialization of other technologies.

The smoke flow has become commercially available for decades. The most modern and widely accepted hobbies are chemical absorption and physical separation. Other technologies include loop cycles such as membranes and chemical loops or calcium loops. In fact, the most suitable capture technology for this program depends on the many factors, including the initial and final desired cavity.

Configuration and consumption of concentration, working pressure and temperature, gas flow, integration and cost reasoning with initial objects.

Ccus Technology Innovation

And chemical solvents (eg, ethanolamine compounds). This is generally performed in two columns for absorption, and the other releases Pure Co and works at higher temperatures.

And regeneration of chemical solvents for further work. Chemical absorption by amine -based solvents is the most modern joint.

Division Technology (TRL 9-11). It has been widely used for decades and is currently a small and large project around the world (e.g., Canada’s dam and United will come and come. Used in scale projects.

Saudi Arabia’s EOR Demonstration Project). Other CCUS projects (for example, Norwegian cement production, energy to Norway and the Netherlands) also plan to use chemical absorption in COS.

Northeast Us Offshore Wind Projects Ramping Up

It is based on adsorption, absorption, ultra -temperature division or dehydration and compression. Physical adsorption uses solid surfaces (for example, activated carbon, alumina, metal oxide or zeolite), while physical absorption uses a liquid solvent (eg, selectol or direct). After being captured by the adsorbent,

It is released by temperature (adsorption of temperature swing) or pressure (adsorption of pressure swing [PSA] or vacuum).

Currently, physical separation is mainly used for processing of natural gas and ethanol, methanol and hydrogen, and nine large plants (TRL 9-11) are all in united. In general, they use brand solvents (Texas’s intensity factory, Great Plane factory in North Dakota, lost gas factories in the voming, and Texas’s Terella Natural Gas Factory). Illinois carbon capture and storage projects are the largest CCUS objects applied to biofuel production and depend on dehydration and compression (due to the composition of gas flow,

Palpal Division is involved in fuel combustion using almost pure oxygen and subsequent capture.

Greentown Labs And Vineyard Wind Launch The Offshore Wind Challenge To Accelerate Technologies That Protect Marine Life

Technology readiness level definition, dod technology readiness level, software technology readiness level, technology readiness level 6, trl technology readiness level, offshore wind technology, technology readiness level uk, technology readiness level assessment, technology readiness level, technology readiness level examples, wind offshore, nasa technology readiness level