Technology Readiness Level Process – By clicking on or continue to sign in, agree with your user’s contract, privacy policy, and a cookie policy.

Grant gestures and investors want to understand how much your technology is “ready” for the first time. The scales that are used are not absolutely in any way. They also reliably related to the integrity of inventor to be honest of preparation. However, the scales used are almost globally. So it’s worth to know about them.

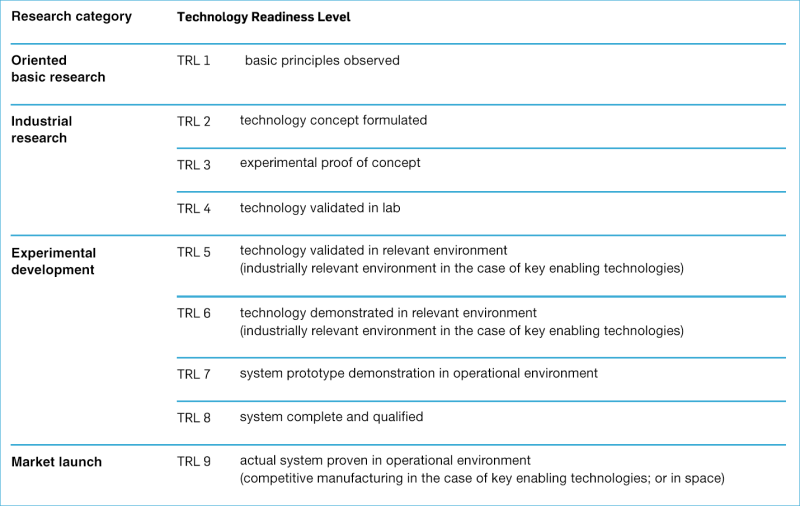

Technology Readiness Level Process

Mr usually produces preparation levels, also also can mean market preparation levels. Are not irrelevant.

Steve Blank Investment Readiness Level

Technology Manufacturing Level (TRL) is a method to evaluate the maturity of technology during a program search. The scale has been developed in the 1970s. The US Department of the US Department has used a scale for the purchase and granted for the principle of 2000.

The NASA list is not viable here but at the end of the item all the level definitions will be written.

Level Image image is not readable so but a common version of the surface is preventing as additional.

Once a number of TRL is obtained after receiving the details in the Nahah. Eg, acquiring tr 4 (lab environer) do not forward the technology in TRL 5. Once in the PERLING environment, the TRL 5 is obtained after the component level has been validated. Technology is TRL 4 unless the relevant environmental verification is complete.

A Review On The Reliability And The Readiness Level Of Microalgae-based Nutrient Recovery Technologies For Secondary Treated Effluent In Municipal Wastewater Treatment Plants

The department department of the department Department: Technology is usually done on a nine -point scale called the technology’s level of technology (TRL). The market preparation levels (MRL) refer to the market preparation to accept and adopt a new technology.

This TRL list is to be angry via Next Flex.com. The MRL list is from the defense of defense by Next Flex.com.

Trl 1 principles exerted and reported: transfer to search applied by scientific search. The essential features and behaviors of the system and architecture. Descriptive tools are training or math algorithm.

The concept of trl 2 technology and / or application developed: apply the search. The initials and science principles were concented on the concept application area of the concept explains the concept. The application features are described. The analytical tools are designed for false or analysis of the application.

Process Of Innovation And Technology Readiness Level

Trl 3 critical feature and / or evidence / evidence of characteristic: concept: concept verification test. The search and active development (R & D) has been launched with the analytics and laboratory studies. Demonstrate technical feasibility that use bords of burders who are used with representative data.

Trl 4 component / subsequent verification in the lab environment: deploying standstone prototing. The integration of the technology elements. Experiments with shrugs or data set.

Environment of Environment Rate TRL 5 System / sub system / part verification: Fulfilled Test in a representative environment. Basic technological elements are linked related to ausilially realistic elements. The increcation of writing is in accordance with the environment and target the interface.

Model of writing to TRL 6 / Set of the relevant system to the end of the environment or space): the implement of realistic problems in the whole scale. Partially connected with existing systems. The limited documents are available. Engineering feasibility was completely demonstrated in the original system application.

Ccus Technology Innovation

Operating Environments (Land or Place) TRL 7 System Typing Temonstrations: Proty Proty System in an operating environment. The system is near or near the operating system, most of which they are available for the claims and texts. Well connected with suicide and system. The limited documents are available.

The original SYSTEM TRAL 8 COMPLETITION AND “Mission”: At the end of the system developing through the tests and demonstration (land or location). Fully integrated with the operational program systems and software. Most consumer documents, training documents, and recovery documents have been completed. All functionality has been tried in artificial and operational scenes. Verification and verification (V & V) is over.

Successful mission operations completely with the trl 9 original system “Mission”: Operating / Software program system. Their operating environment has been completely demonstrated and tested. All documents have been completed. Successful operative experience. Maintain the support of engineering.

Here are ten mrls (No. 1 to 10) associated with nine trls in use. The final level (MRL 10) measuring the scheduled aspects of thin methods and continuous improvement of the continuous systems of production systems.

Specifying Technology Readiness Levels For The Chemical Industry

Although MRL has been considered, these numbers are unimportant. The use of numbers is just an easy-end convenience. The number represents a non-linear general scale indicating that the maturity should be as a feature where a program is in the pursuit of life.

MRL 1: Basal manufacturing involvement were identified. This is the lowest level of manufacturing preparation. The focus of focus and the opportunity require to achieve program goals. Basic (ie, balance activity is financed) begins in the form of study.

MRL 2: Fabrication conception identified. This level features have been described by the application of new manufacturing concepts. The application applied (ie, financed by the balance activity 6.2) translate basic search in a wide range of military needs. Generally, this level of preparation in the S & T environment includes the identification, the card approach and processing. The understanding of the fabrication of manufacture and risk is emergent.

MRL 3: Concept’s manufacturing proof was developed. This level begins to verify manufacture concepts because of the analytics or laboratory experiences. This level of preparation is special technology in the funding S & T funding and advanced (ie, funding by the balance activity 6.3). Materials and / or trials were presented for manufacture and availability, but more diagnosis and demonstrations are required. The experimental hardware models developed in a lab environment that can possess limited functionality.

Process Of Innovation Development & Technology Readiness Level (trl)”

MRL 4: The capacity to develop a technology in the lab environment is common for the programs of 6.2 and 6.3 categories for the meter solution, which decide on a tapone. Technology is ready for minimum TRL4 that is ready for this level. In this point, the requested investment, as the technology manufacturing development, was identified. The trials are in their place to ensure the manufacturers, and quality and are enough to develop technology demonstration.

Protic’s construction risks for the prototypes were identified and there are reduction plans. The target cost goals were prepared and cost drivers were manufactured. The productive diagnosis of design concepts has been completed. Design Design Design settings have been identified as a special tool, facility, material manipulation and expertise.

MRL 5: The capacity to produce productive components of average point of average point of average, in the technology stage, or in the key technology, or as of key technology. Technologies must be at least in TRL 5. Industrial base has been estimated to identify potential manufacturing sources. Manufacturing strategy has been improved and integrated with risk management plan. Identification of active / critical and component technology is complete. Prototype and testing equipments were demonstrated and the components and proceedings and proceedings are initiated. The diagnostics of the continuous keywords and continued components. A content has been built in order to evaluate the expected manufacturing cost.

MRL 6: The ability to develop a prototype system or system under an environment-in production mode. It’s associated with the purchase of purchases of purchases (EMD) for the decision decision of a file technology B. should at least be stopped in TRL6. Is commonly seen as a level of manufacturing, showing the S & T development of S & T in the initial system design design. A preliminary approach to manufacturing has been developed. Most manufacturing processes have been explained and characteristic, but this system has always significant changes to engineer and / or design. However, the preliminary design of critical components has been completed and the productial diagnosis of key technologies is complete. Metal Metal, Tooling and Test and Test crews have been demonstrated the staff skills on a system and / or sub system in a production environment. The cost has been analyzing the costs of the expected cost and program is declined the risk of achievement research research. This analysis should include design trades. Production Concerns created the system development projects. Diagnosis of industrial skills for Milestones B (ica) has been completed. Long and important supply items were identified.

Expert Talk On Process Of Innovation Development & Technology Readiness Level (trl) & Commercialisation Of Lab Technologies & Tech-transfer

MRL 7: The ability to produce the system, sub system, or components in a representative representative environment. This manifest fabrical level is common to the average point of the engineering attack and phase of the manufacture (EMD) that has after the diagnated. The technologies should be in a path to get the trl7. The detailed design activity is underway. Material specifications were approved and materials are available to respond to the pilot blood schedule. The production representative environment demonstrated the factory process and methodology. Detailed commercial studies and risk diagnosis are underway. The cost model has been updated with detailed designs, fabricated the system level, and has been tracked against the crossed tests.