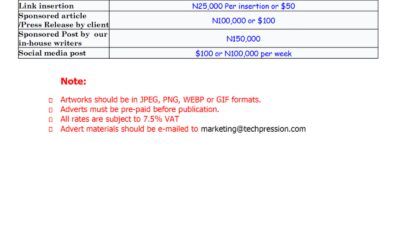

Technology Readiness Level Transfer – An index to measure mature and usefulness of evolutionary technology is the level of technology preparation (TRL). It is increasingly used for comparative analysis, risk management and world financing decisions. So that decision -makers can find out whether technology (product) must be integrated (product) into larger systems (markets) and when. Stan Sadin, NASA researcher, compiled the first TRL scale with 7 levels in 1974. NASA formed this measure in 1989 and then developed its current form of 9 levels (right), which is still used and has been used inspires a lot of “precision level” variations of scale so far.

Among the countries adopted by this TRL scale are Canada, the United Kingdom, Australia and of course European countries. The scale is increasingly adopted by many organizations, in particular, but without limiting itself, the OECD, the EU, NATO and NAMSA. To date, NASA has led many scales of “level of preparation”, including the levels of preparation for reuse (RRL) (for software), levels of preparation for interaction (to interact with Other systems), the driver’s preparation level (for space vehicles) and the level of preparation for the metric application (the level of preparation for the metric application (for funded projects). Due to specific needs, several Organizations, corporate capitalization companies and rating companies are developed such as the level of manufacturing preparation, a commercial preparation index and the level of preparation for investment.

Technology Readiness Level Transfer

Today, the business world is more chaotic than ever, what many call Vuca (volatile, uncertain, complex, ambiguous) or even super vuca (vibrant, unreal, mad, magnificent). The values are not created by unique entities but by networks. Even customers are involved in the design, creation and financing of products and services. There are no more traditional industry limits. All the work is multidisciplinary, the cross and transnational industry. It is difficult to claim a competitive advantage and more difficult to maintain. No value depends on a single technology or a resource. SMEs (small and medium -sized enterprises) must be fast, flexible and agile. Being an established company does not allow any market share or customer satisfaction. Even large companies use a beginning of reflection that emphasizes validated learning and continuous innovation. Without these practices, disruptive innovation is impossible. Otherwise, companies limit not only their growth but also risk their survival.

Technology Readiness Levels For Machine Learning Systems

To transform very interesting ideas and technologies into a company that can continue to innovate for years, a discipline is necessary. – Steve Jobs

We need standard, systematic views and sharing innovation management, market reduction in market, making smart investments and setting up product market adjustment. TRLS is one of the key tools that strengthen our decisions. Essentially, TRLS is not interested in the research and development process as such, but the step -by -step step of innovation activated by research and development.

The image on the left shows the rise of NASA TRL technology. You can see two other TRL processes on these links: the AHM of the main engine and the friction transfer welding. With the exception of being part of the relevant research partnerships, companies do not generally focus on TRL 1-3 activities, because only researchers can ignore marketing 🙂 Even innovative SMEs are intensive research starts mainly from ‘TRL 4 activities. rather than scientific explanations. It is widely accepted that innovation does not need to be invented and that not all devices turn into innovation. Indeed, most successful innovators in existing technologies and integrators are the best way to solve a particular customer problem. This work still requires a lot of research and experimentation to extend the practical operations of known scientific principles. Then, the most difficult challenge of SMEs is to design, implement and provide magic experience to customers.

Science may never offer a better communication system than coffee break. – Earl Wilson Importance TRLS IN PMES INSTRUMENT

What Are Technology Readiness Levels (trl)?

This year, the European Commission (EC) has launched its brand new research and innovation program, Horizon 2020, which will last until 2020. In this program, the CE attaches great importance to impact, results and results to the marketing of sustained research and innovation. Consequently, Horizon 2020 seeks to attract SMEs more than ever in many aspects. It even has a dedicated SME tool to support activities that are closer to the use of the market. As you can guess, Horizon 2020 and PME Instrument refer to TRLS in their selected support process as Grant as well as the subsequent support process. The SME instrument is specifically intended for candidates who offer innovation projects that have reached TRL 6 as a minimum (or the equivalent for non -technical innovations). This generally means that the activities offered should take place in an active or production environment.

A SME tool does not define its own TRL scale. It refers to the same scale as all the other financing plans and calls to 2020. The definitions of these TRS are listed in the general attachments, the only and the only guide for the TRS of the 2014 -15 work program , as below. However, this program also suggests specific interpretations about TRL in terms of criteria to meet or milestones to show at all levels. Consequently, TRLS aims to be more relevant and more effective in financing and project management decisions.

TRL 5 technology validated in a relevant environment (industrial environment for key activation technologies)

TRL 6 technology shown in a relevant environment (relevant industrial environment for enabling technologies)

Commercialize An Invention

TRL 9 Real system tested in an operational environment (competitive manufacturing for key activation technologies; or in space)

Exception: note the questions frequently asked about “health, demographic change and well -being” a subject can be read -2015 … in particular, the general reference to the use of TRL in SMEs does not apply At PHC 12. The use of TRL is examined for WP2016/2017. “

Previous studies on the TRL assessment have highlighted a certain confusion among industry professionals, some of whom are explained below. They would help experts assign the right TRL to their project at the right time to allow project management more effectively and the possibility of higher funding.

Almost all developers and users of the TRL scale in various industries believe that TRL 6 is a major change in research and experimentation to implement and market real life. This level requires critical decisions to be made if an additional investment for a project should be taken, and if necessary, how to get the most out of it. Several presenters of CE have also recognized its practical meaning. From TRL 6, the maturation phase is more motivated by guaranteeing management confidence than by research and development requirements. This is a cutting point where individual technologies and independent elements do not concern more discussions. From now on, only global scalable technology, the system or the product is placed in a holistic manner and a TRL number accordingly. There is no more room for the concept but only for tests.

Specifying Technology Readiness Levels For The Chemical Industry

Due to its vital importance in the evaluation of technology, a common understanding of TRL 6 is essential. It starts with the definition of technology, “by applying information in practice so that something completely new can be done, or something can be done in a completely new way”. Then, the descriptions come from key terms commonly used in TRL 6 discussions.

Prototype: a physical or virtual model used to assess the technical feasibility or the manufacturing or military utility of technology or process, concept, the final element or the specific system.

Model: a functional form of the system, generally reduced in scale, near or in the operational specification. The models will be sufficiently hardened to allow the demonstration of the technical and operational capacities required from the final system.

Display / pilot: actions aimed at validating the technical and economic viability of technology, product, process, service or new or better solution in an operational environment (or close to the operation).

Technology Assessment And Transfer

Duplication of the market: actions intended for the application / locate the “first” on the innovation market which has already been shown but has not yet been applied. “Firstly” means at least new in Europe or at least new in the applications in question. Several market applications are not included.

Critical technology component: a new or new component on which technology or the system is based to succeed in development or to successfully meet the operational threshold requirement of a system.

Operational environment: the environment that meets all the operational requirements and specifications required for the final system, including the platform / packaging.

The main enabling technologies: nanotechnologies, micro and nanoelectronics (including semiconductors), photonics, advanced materials, advanced manufacturing systems, biotechnology and other strategic engines such as space.

Innovation Needs In The Sustainable Development Scenario

The TRLS manual for space applications, a large guide published by ESA, indicates that the details of an appropriate technological preparation assessment process depends on the details of the applications of the potential system and the program requirements. And lists the principles below vulnerable to specific adaptation to technology. At TRL 6, while not only including technologists involved in the display, it must also include potential customers. In fact, it must be organized and operated by customer organization rather than technological organization. Below is officially required by a call for instruments Horizon 2020 or SME. However, ESA clearly has big advice on how to find TRL 6 better even if the project does not target a SME tool.

Detailed definition of “TRL 6”: at TRL 6, a representative model, a prototype or a system, which would go far beyond the level of bread bread component must be tested, in a relevant environment. If the only relevant environment to show progress is the operational environment, authentication must be displayed in the operational environment. At TRL 6, several (or several) new technologies will generally be integrated into the demonstration, therefore an active model, sub-scales (but can be on a scale) of the system