Technology Readiness Level Trl 3 – By clicking, keep joining or entering, you accept consumer agreements, privacy policies and cookies policies.

Grants and investors are ready to understand how much your “ready” technology is in the main time. The scale used do not match. It also relies on the inventor of the inventor to be honest about readiness. However, the scale used practically accepted in the world. So you should know about them.

Technology Readiness Level Trl 3

MRL is usually a level of production readiness, although this may also mean the level of market readiness. These two have nothing to do.

Readiness Assessment For Ide Startups: A Pathway Toward Sustainable Growth

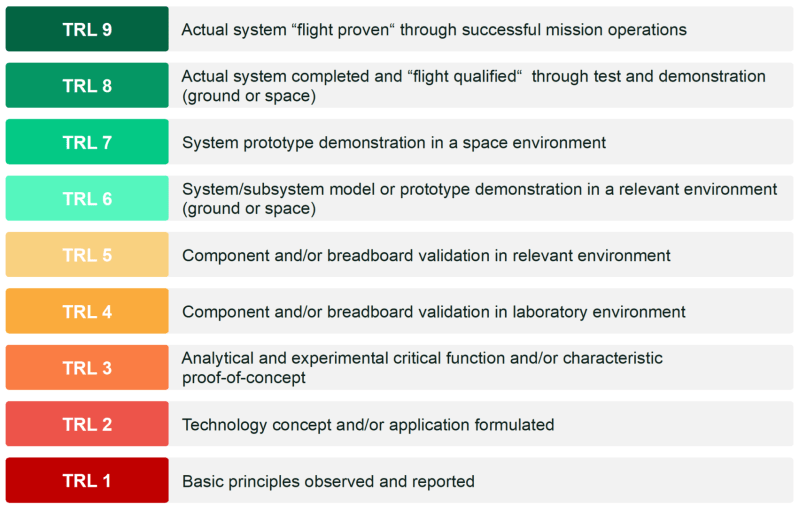

Technology readiness standards (TRLS) are a way of assessing technological maturity during the program. The standard was organized in NASA in the 1970s. Since the 2000s, the US Department of Defense has used the purchase and grant rewards rate.

The TRL NASA list is not recommended here, but at the end of the article, all standard definitions will be written.

The standard TRL image is not read so, but the standard version of the standards is provided as an attachment.

The TRL number is found as soon as the information on the chart was found. For example, the next TRL 4 (laboratory medium) does not manage technology for TRL 5. Technology remains TRL 4 until the proper environmental confirmation is completed.

Human Readiness Levels (hrl)

Energy market process: Technology readiness is usually measured at a nine -step rate known as technology readiness (TRL). Market readiness standards (MRLS) Refer to the market will accept and accept new technologies.

This TRLS list comes from NASA via nextflex.us. MRLS list – from Dept of Aremation via nextflex.us.

TRL 1 Basic principles have been observed and reported: the transition from research to applied research. Important characteristics and characteristics of systems and architecture. Explanation of instruments is the formation of inventory or algorithms.

TRL Technology Concept 2 and/or applications are created: Studies. Scientific theories and principles focus on a particular use sphere to define the idea. Described software characteristics. Analysis tools are intended for oral or software analysis.

The Trl Framework: The Right Choice For Mass Production?

Analysis of TRL 3 and key experimental feature and/or confirmation character: confirmation confirmation. Studies and development (NDDKR) were initiated by analytical and laboratory studies. Exhibition of technical capabilities using a bread board or implementation of a brush that is implemented by representative data.

Checking part 4 TRL/small system in laboratory conditions: prototype and implementation of tests. Inclusion of technological objects. Experiments with full problems or data kits.

TRL 5 System/Low System Verification System/Component in appropriate conditions: Complete prototype testing in representative conditions. The main technological objects that are included in the real elements that support. The implementation of prototypes corresponds to the environment of focus and interaction.

6 System/System/System/System or Protatipping of the Procession under the appropriate end (land or space): realization of prototypes on real problems. Part is included with existing systems. Small documents are available. The engineering capabilities are fully shown in the real use of the system.

Technology Readiness Levels (trls) Explained

The TRL 7 system is displayed in the operative environment (land or space): The prototype system is displayed in the functional environment. The system is near the productivity system, and many features are available for protest and check. This is good -integrated with securities and supplements. Small documents are available.

The actual TRL 8 system ends with “graduated messages” through a test and demonstration in an operational setting (land or space): the end of the system development. It is fully integrated from the performance device and software systems. Many users of documents, training documents and maintenance documents have been completed. All performance measured under imitation and work. Authentication and authentication (V & C) has been completed.

TRL 9 Actual System “Message has been certified” through successful mission operations: it is fully integrated with software/software systems. The actual system is fully shown and tested in its work. All documents are completed. Good work experience. Develop engineering support in place.

There are ten MRL (calculated from 1 to 10) that connect to the nine TRL used. The final level (MRL 10) measures slim practice and constant improvement of production systems.

Technology Readiness Level (trl): Guide 1-9

Although MRL is calculated, the numbers themselves are not important; Using a number is a simple meeting. The numbers are a non -linemal level that determines what maturity should be a task when the plan is in the life cycle.

MRL 1: The main production results are defined. This is the lowest level of readiness for production. The goal is to solve production restrictions and the capabilities needed to achieve software goals. Major studies (ie, which are funded by budget activity) begin in the study system.

MRL 2: Production concepts are identified. This standard is a reputation to explain the use of new production concepts. The study used (i.e., which is funded by budget activity 6.2) translates basic research into a solution for certain military requirements. Usually this level of readiness in the S&T environment includes identification, paper studies and analysis of material methods and processes. There is an awareness of the possibility of production and risk.

MRL 3: Confirm the concept of the concept. This standard begins confirmation of production concepts with analytical or laboratory experiments. This level of readiness is an example of technology in the forms of financing S&T studies used and advanced developments (ie, which are funded by budget 6.3). Materials and/or processes were shown to make and availability, but additional assessment and protest are needed. Types of experimental devices have been developed in laboratory conditions that may have less performance.

What Are Technology Readiness Levels?

MRL 4: The ability to develop technology in laboratory conditions this level of readiness is characteristic of S&T programs in the budget 6.2 and 6.3 and acts as a criterion for leaving the materials analysis (MSA), approaches the decision. Technologies have been identified at least TRL 4. At this point, the necessary investments such as developing production technology were identified. There is also enough processes to ensure the manufacture, production and quality to provide protesters.

The risks of production were determined by construction prototypes, and the reduction plans are located on the spot. Target expenses were set and the cost of production drivers were identified. The assessment of the production of the concepts of the structure was completed. Important standards for structure performance, and specific tools, equipment, equipment processing and skills have been identified.

MRL 5: The ability to manufacture equipment modeling in the appropriate production conditions this level of maturity is a central model in the technological development section, or in terms of key technology, near the central stage of advanced technological protest (ATD). Technologies should be ripe at least 5 TRL. The industrial fund is measured to detect production sources. Production strategy has been refined and integrated with the risk management program. Detection of Enable/Important Technology and Equipment has been completed. Prototype equipment, tools and testing equipment, and staff skills were shown on materials in the appropriate production conditions, but many production processes and processes are still being developed. Development of production technology has begun or continued. Production of basic technologies and equipment is evaluated. The cost model is built to assess the estimated cost.

MRL 6: The ability to create a model system or a small system in the appropriate production settings. This MRL is related to the read B -Encouraging program B -Reburation by entering part of the engineering and development (EMD) access. Technologies should ripen at least 6 TRL. This is usually seen as a level of readiness for production, which means completion of S&T development and acceptance in the original system structure. The original production method is developed. A large number of production processes were also described, but there are still significant changes to the engineer and/or structure in the system itself. However, the initial design of the necessary equipment was completed and the assessments were completed for the production of basic technologies. Prototype equipment, tool equipment and test equipment, and staff skills are given in systems and/or in a small system in the appropriate production conditions. The cost analysis was made to assess the estimated production costs in accordance with the expense goals, and the plan led to a reduction in the risk to meet the cost requirements or to create a new foundation. This analysis should include design design. Production ideas have created plans for the system development. Evaluation of industrial potential B (ICA) has been completed. Long and important distribution elements have been identified.

Adaptation Of The Technology Readiness Levels For Impact Assessment In Implementation Sciences: The Trl-is Checklist: Heliyon

MRL 7: The ability to produce systems, small systems or equipment surrounded by a production representative. This level of readiness for production is usually the stage of the middle of engineering and production development (EMD), which leads to evaluation after -cdr. Technology should be on the way to reaching TRL 7. The Deep Structure Labor System is enabled. The classification of the equipment was approved and the equipment is available to meet the pilot construction schedule. Production processes and processes are shown in the production environment. Deep business research and risk assessment are underway. The cost model was updated with detailed designs, tapped to the level of the system and controlled against the highlighted goals.